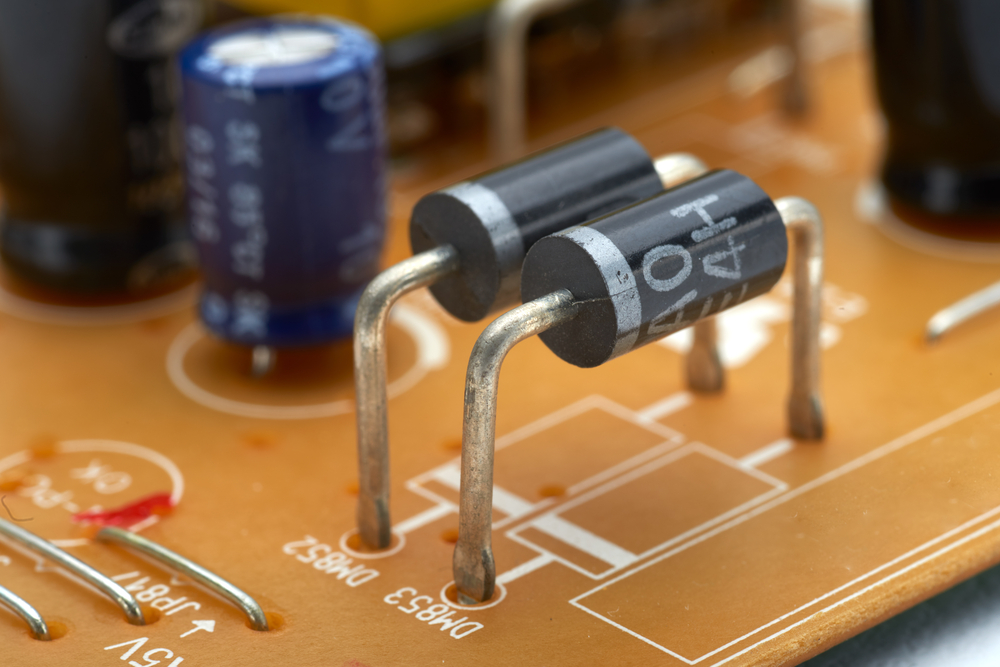

A semiconductor falls somewhere close to a guide and a cover. Therefore they are regularly used to make Coordinated Circuits. A genuine illustration of a semiconductor material is silicon. This is the most ordinarily involved material in the microelectronics business in light of multiple factors. One of the essential reasons is its low cost and accessibility. TV, radio, phone and other electrical or hardware merchandise have semiconductor gadgets in them. The materials utilized in semiconductor gadgets are able to do to some extent directing power, dissimilar to full transmitters of power like aluminum, copper and steel. A coordinated circuit has different small parts like resistors, diodes and semiconductors. These small parts can harm effectively in the event that a lot of current goes through them. In this way, a silicon wafer or substrate is generally utilized as a base as opposed to a guide.

This kind of wafer likewise gives a superior consistency for current stream contrasted with a guide after extraordinary treatment. An incorporated circuit is typically comprised of a wafer, resistors and other electronic chips. This sort of hardware board assumes an essential part for the working of electrical or gadgets. On account of evacuation interaction, dry or wet carving strategies can be utilized to eliminate material from the photodiode array detector semiconductor substrate. Designing is forming or reshaping of the substrate. One of the normal strategies is lithography. One of the most widely recognized strategies for electrical property alteration is particle implantation. Wafer testing is done to test assuming it meets the necessary rules. With regards to making a dainty layer of substrate as on account of a PCMCIA or a shrewd card, crushing is performed to diminish the thickness. Other key cycles are kick the bucket arrangement and IC bundling. Kick the bucket readiness includes mounting chips onto a substrate and bite the dust cutting. For IC bundling, a portion of the fundamental cycles are incorporated circuit holding and epitome. For incorporated circuit holding, wire or thermosonic holding can be utilized.

This kind of wafer likewise gives a superior consistency for current stream contrasted with a guide after extraordinary treatment. An incorporated circuit is typically comprised of a wafer, resistors and other electronic chips. This sort of hardware board assumes an essential part for the working of electrical or gadgets. On account of evacuation interaction, dry or wet carving strategies can be utilized to eliminate material from the photodiode array detector semiconductor substrate. Designing is forming or reshaping of the substrate. One of the normal strategies is lithography. One of the most widely recognized strategies for electrical property alteration is particle implantation. Wafer testing is done to test assuming it meets the necessary rules. With regards to making a dainty layer of substrate as on account of a PCMCIA or a shrewd card, crushing is performed to diminish the thickness. Other key cycles are kick the bucket arrangement and IC bundling. Kick the bucket readiness includes mounting chips onto a substrate and bite the dust cutting. For IC bundling, a portion of the fundamental cycles are incorporated circuit holding and epitome. For incorporated circuit holding, wire or thermosonic holding can be utilized.

Average instances of IC epitome processes are plating and baking. Incorporated circuit testing is basic to actually look at the general elements of microprocessors and substrate. It is the last testing of the entire gadget prior to bundling and shipment to a client. To sum up, semiconductor gadgets are utilized in all the flow electrical or hardware items available. The assembling processes for these gadgets include many advances. The significant cycles are wafer handling; kick the bucket readiness and IC bundling. Incorporated circuit testing is completed to really look at the general elements of all chips and substrate as conclusive review prior to bundling and shipment to a client. Jessica entered the Semiconductor Assembling field in 1998 and is presently the pioneer behind Rebel Valley Microdevices in 2003. As Pioneer and President, Jessica has laid out the organization as an elite silicon wafer provider and Actual Fume Statement administrations.