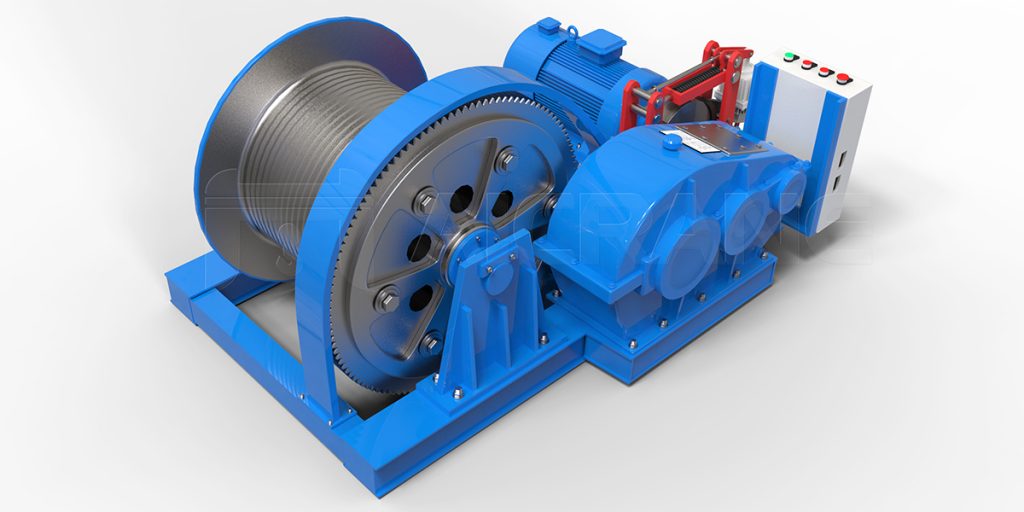

The advent of cutting-edge electric winches and hoists has ushered in a new era marked by precision, efficiency, and unparalleled performance. These state-of-the-art devices have redefined the way industries approach lifting tasks, offering a potent combination of power and precision that significantly enhances productivity and safety. At the heart of this technological revolution are electric winches and hoists that leverage advanced engineering to deliver exceptional lifting capabilities. Unlike traditional manual methods or outdated mechanical systems, electric winches and hoists are characterized by their ability to effortlessly handle heavy loads with unmatched precision. This precision is particularly crucial in industries where accuracy is paramount, such as manufacturing, construction, and logistics. One key feature that sets electric winches and hoists apart is their variable speed control. This allows operators to fine-tune the lifting process according to the specific requirements of each task. Whether it is a delicate operation that demands a slow and controlled lift or a swift movement to meet tight deadlines, electric winches provides the flexibility needed to adapt to diverse scenarios. The result is not only increased efficiency but also a reduction in the risk of accidents and damage to valuable goods. Moreover, the cutting-edge technology incorporated into these electric lifting solutions ensures a high level of reliability and durability.

The robust construction and use of quality materials make electrical winch and hoists capable of withstanding the rigors of demanding industrial environments. This longevity translates into a cost-effective investment for businesses, minimizing downtime and maintenance expenses. Safety is a paramount concern in any lifting operation, and electric winches and hoists excel in this regard. Equipped with advanced safety features such as overload protection, emergency braking systems, and fail-safe mechanisms, these devices provide operators with peace of mind. The incorporation of smart technologies and sensors enhances situational awareness, preventing potential accidents and ensuring the well-being of personnel. The advent of wireless remote control technology further amplifies the advantages of electric winches and hoists. Operators can now control the lifting process from a safe distance, optimizing visibility and reducing the risk of injury. This level of control is especially valuable in confined spaces or hazardous environments, where traditional methods may pose additional challenges.

In addition to their functional benefits, electric winches and hoists contribute to environmental sustainability. With a focus on energy efficiency and reduced emissions, modern electric lifting solutions align with the growing demand for eco-friendly practices in industry. This not only reflects a commitment to corporate social responsibility but also positions businesses for compliance with evolving environmental regulations. In conclusion, the deployment of cutting-edge electric winches and hoists heralds a transformative era in material handling and lifting operations. The power of precision lifting offered by these advanced devices empowers industries to achieve new levels of efficiency, safety, and environmental responsibility. As businesses seek to optimize their operations in an ever-evolving landscape, embracing the capabilities of electric winches and hoists becomes not just a choice but a strategic imperative for success in the modern industrial age.